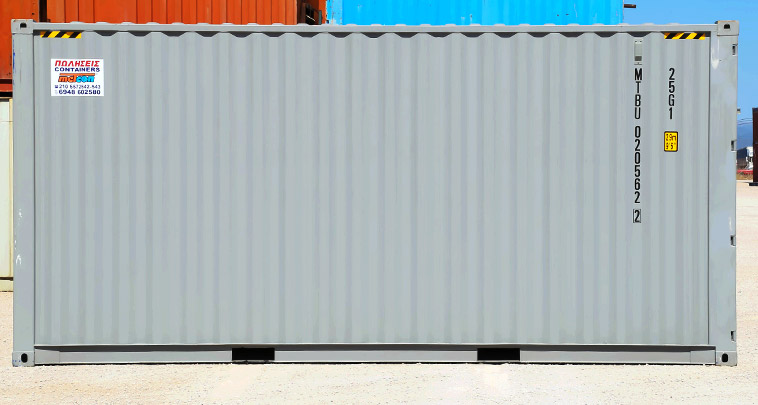

20 HC container

External dimensions (length x width x height): 20′ x 8′ x 9′ 6” – 6,01m x 2.44m x 2,89m

Internal dimensions (length x width x height): 19′ 4.3” x 7′ 8.6 x 8′ 10” – 5.9m x 2.35m x 2.69m

Cubic Capacity: 1,35ft³ – 37,2m³

Tare Weight: 4,300 lbs – 2.250 kgs

Max. Gross Weight: 67,200 lbs – 30.480 kgs

Payload (Net Weight): 62,038 lbs – 28.140 kgs

Permissible Weight (over the roof’s corners posts): 476,200 lbs – 216.000 kgs

Structure: Steel shipping/cargo containers walls are made from 14 gauge, 0.075 inch corrugated sheet steel panels that are welded to the main structure. The top and bottom side rails and end frames are 7 gauge tubular steel. The steel used to build modern shipping/cargo container is a corrosive resistant high-strength low-alloy steel.

The roof of shipping/cargo containers is constructed with die-stamp corrugated steel sheets with a certain chamber at the center. The roof’s main purpose is to keep out the elements.

The bottom of the shipping/cargo container has 3-4 mm thick cross members that have recesses along the bottom side rails, which allows them to be lifted with special straddle carriers. The floor of the shipping/cargo container is 28 mm thick with 19 ply treated plywood screwed into the structural cross members.

Care instructions

1. The container should sit on a level surface, otherwise the door will not open and close properly. If the soil that would be placed is not level, then we recommend to place a concrete block under each corner of the container. The blocks should be placed under the iso – container posts in the 4 corners.

The corner posts of the container are each 17 to 18 centimeters (7 inches).

2. We recommend you to grease the door, the hinges and the lock rods on the door at regular intervals in order to preserve a normal function of the doors.

3. Make sure that all products are dry before loading. If damp goods are placed inside the container, then this will cause condensation.